Off-Site Wall Panel Construction

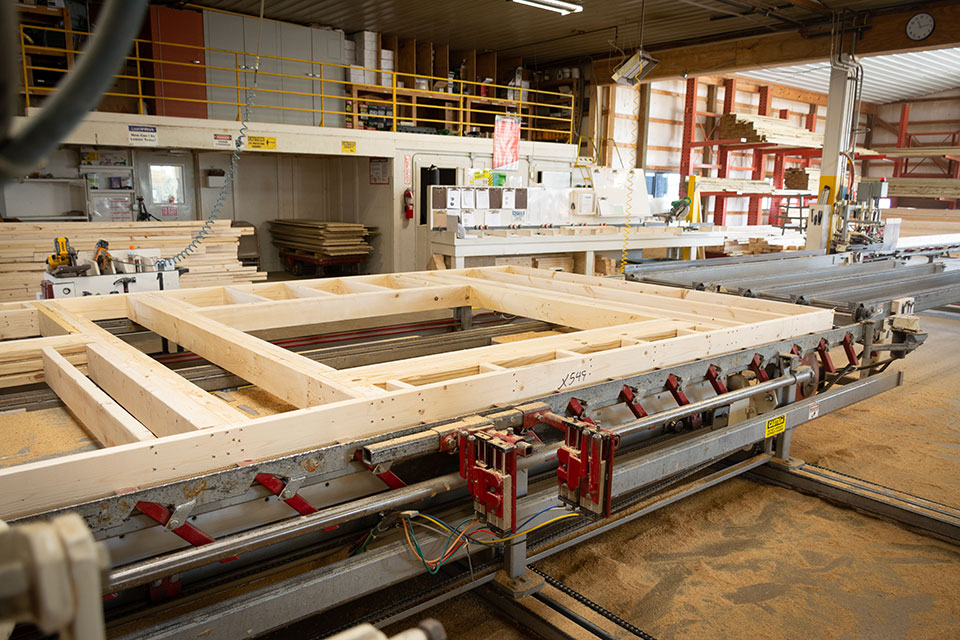

Several decades ago JDM Structures developed the optimal construction process for wall panels in the shed and home industry. We expanded this system to offer a one-stop material and labor package that includes off-site framing and on-site installation.

Why JDM Pre-Fab Wall Panels?

WORK SMARTER

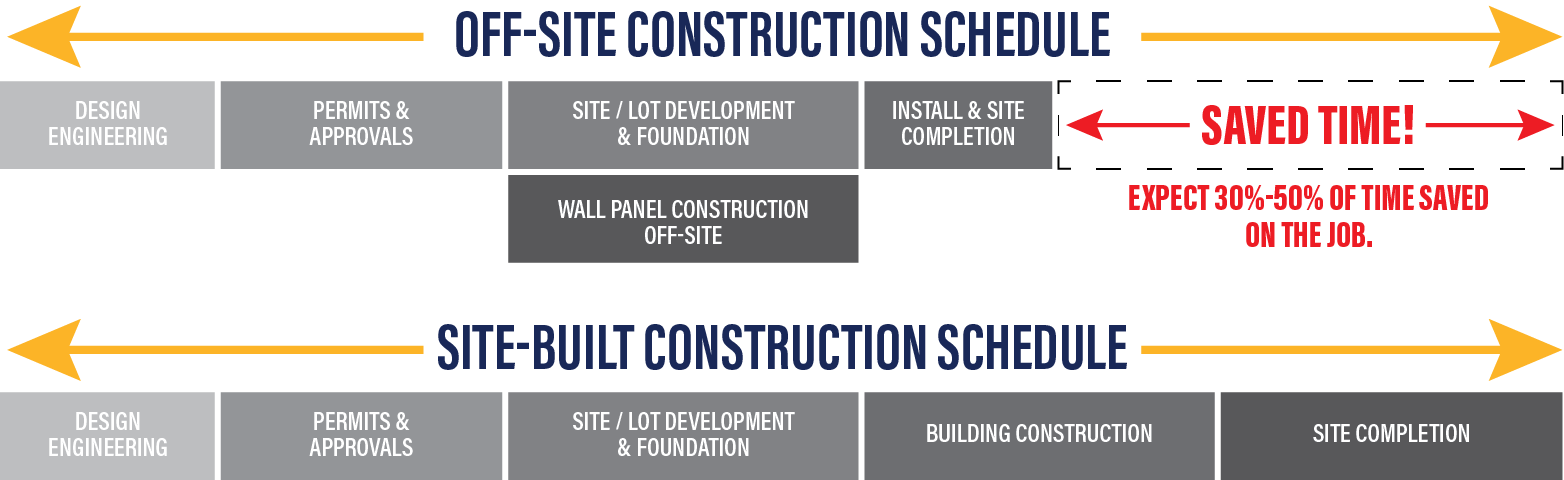

Shorten cycle times—get to the next project more quickly.

LESS LABOR

Uncover lower costs and higher profits.

EFFICIENT

The JDM method creates 30% less material waste.

BOOST PRODUCTION

Increase annual production by 25%

RELIABLE

Our wall panels show up on time and are built right the first time.

SUSTAINABLE

Off-site construction is an energy efficient and emission reducing approach.

Commercial and Residential Wall Panel Construction

Our experience has allowed us to delivered excellence time after time. Once a general contractor works with us once, they always come back to us for their next job. JDM wall panels have been framed and installed for use in

• Nursing homes & assisted living facilities

• Hotels

• Apartment housing

• Multi-family housing

• All types of residential homes

GETTING A PROJECT BACK ON SCHEDULE

Our team has taken projects like a four-story motel and completed the dry-in within 22 working days. We have also helped general contractors recover a full month on a project. Our crews are there on schedule with the materials needed.

Pre-Fab Wall Panel Resources

Test Study

Two identical 2,900 square foot ranch homes were framed side-by-side. One was stick-framed and the other used components. Here are the results.

Total Jobsite Hours to Erect

Total Jobsite Waste Generated

Total Board Foot Lumber/EWP

Stick Built

375.5 hours

15.0 cubic yards

20,643 board feet

Component

152.1 hours

0.5 cubic yards

15,052 board feet

Savings

223.4 hours

14.5 cubic yard

5,591 board feet

Off-Site Building Systems that Help You Win

The benefits are clear with off-site wall panel construction. It saves on time and money, allows for better quality and more reliable construction, and uses more sustainable practices.

Slim Cycle Time

The JDM Wall Panel System can decrease the build time by 30%.

Less On-Site Labor

Off-site panel construction can bring the need for on-site labor in the range of 40%-60%.

Decreased Material Waste

Off-site construction has been shown to create 30x less waste than the stick-framing process.

We are happy to ship our panels to a wider region (500 mile radius), but our crews only travel to the shaded service area in the map.

Panelized Construction Leaders

JDM’s long history in the building industry gives us many advantages on the job site and before we get there.

• We have one of the most seasoned and experienced work forces in the framing industry.

• JDM uses the industry-leading panel design software to create the most efficient and effective approach on each job, for a consistent and reliable result.

• We are continually buying large volumes of lumber, which allows us to have reliable access to materials and competitive and guaranteed pricing—on both materials and labor.

REQUEST A CONSULTATION

Ready to upgrade your job site? Start a conversation with our wall panel team.